Sales Tel

+86-18928379199

1.Raw materials

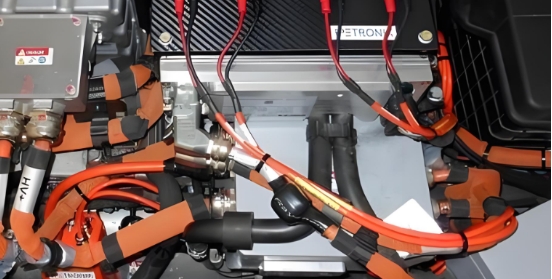

Cable consists of conductor, insulation, filling, shielding, braided tape and sheath, etc., involving conductive materials (such as copper, aluminum), insulation materials, filling materials, shielding materials and sheath materials. New energy vehicle cable insulation and sheath mostly use elastomers, such as TPE, TPU, XLPE, heat-resistant XLPO, PVC, silicone rubber, fluorine elastomers, etc., which have excellent resilience and save space. Automotive wiring harness plug is the key to connecting the electrical lines, can protect the current and signal transmission, its selection is extremely important in the vehicle assembly, because of the many connection points, once the error may cause serious consequences and even traffic accidents.

2.Cable processing

Cable processing enterprises is the core of the industry chain convergence.

The key processes are as follows:

Cutting wire stripping: the wire cutting length is required to be precise, with very small tolerances, the cross-section needs to be flat, the degree of scratches on the copper wire must be in line with the specifications, and there shall be no scattering or bulging after stripping.

Multi-core structure stripping: multi-core cable in stripping, need to remove the filler, and each cable is handled separately, strictly control the copper wire scratching. In the connector assembly, to prevent cable crossover, or a single cable is easy to lead to terminal disengagement by force.

Pre-assembled Tail Attachment: The type of tail attachment is determined by the connector structure, and open and closed bellows are available. If a closed bellows is chosen, its length has a significant impact on the ease of installation. There is no room for error in this process, as if the installation is missed and only discovered after crimping, the semi-finished product can only be scrapped.

Shield layer handling and stripping: Be sure to wear goggles during operation to prevent shielding wire from splashing. Focus on controlling the state of the shielding layer to prevent leakage of wire, piercing the wire skin and other issues. Special attention should be paid to the shielding wire pierced into the wire skin but not completely pierced the situation, although the finished product may be temporarily qualified for electrical performance testing, but the vehicle long-term operation under vibration, may still cause short-circuit and ablation phenomenon.

Closed terminal crimping: Operators should wear finger cots to prevent sweat contamination (silver-plated terminals should also be stored away from light). Strictly follow the high-voltage harness closed terminal crimping requirements, and according to the structure of the connector design special crimping positioning tooling. After crimping is completed, make sure that the height and width values are stable, and wire residues must not fall into the connector. Need to focus on the shielding wire crimping strength, too heavy easy to make the shielding wire fracture as a whole, can not realize the electrical function; too light will lead to the cable out of the function failure; if the shielding wire scattered in the connector, after loading the connector will lead to ablation.

Detection: electrical performance testing includes conductivity and insulation voltage testing, high-voltage testing time in the test phase for each point 1 minute, the actual production according to the specific circumstances between 2-10 seconds, but not less than 2 seconds. Mass production also need to carry out air tightness testing to ensure product quality and safety.

JMK's fully automated wire harness equipment is trusted for its superior quality.