Sales Tel

+86-18928379199

|  |  |  |

Wire Cutting/Stripping/Dual-end Crimping

Product Introduction:

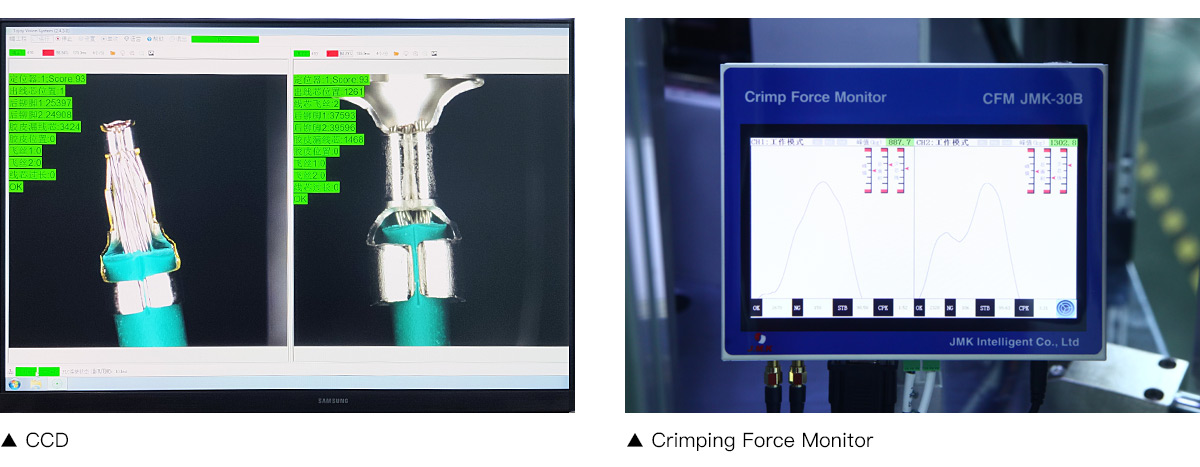

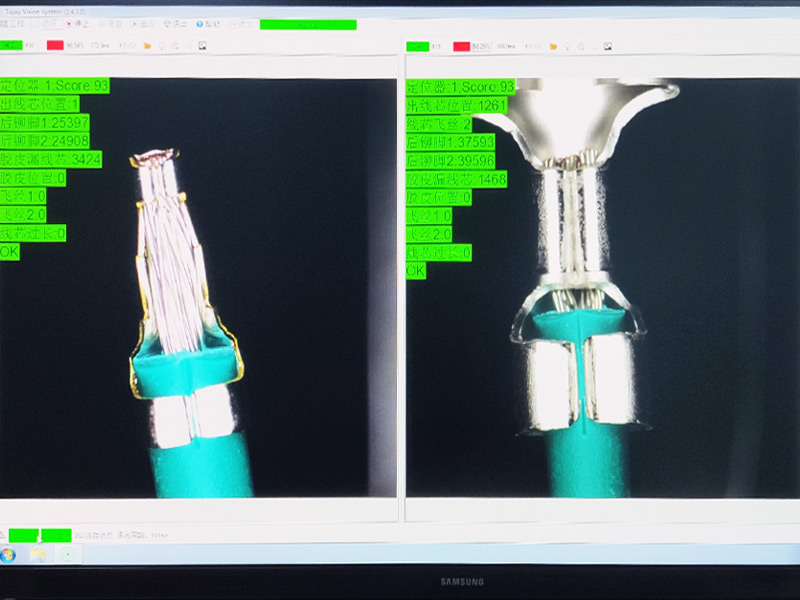

High cost-effectiveness, compact size, PLC control, support for wire cutting, single and dual-end stripping, dual-end crimped, optional pressure monitoring and CCD visual detection system.

Product Feature:

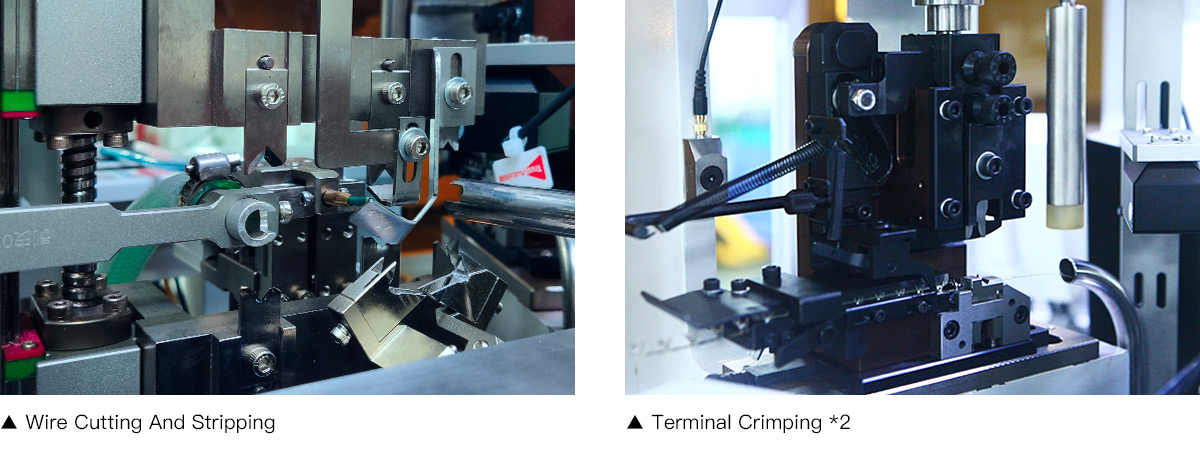

1.Features a fully closed-loop flexible wire feeding system with a rubber belt mechanism to protect the wire surface and enhance feeding accuracy.

2.Incorporates a network-driven system to meet the rigorous industrial processing demands of photovoltaic wires.

3.Utilizes imported servo motor drives to ensure high precision, efficiency, and operational stability.

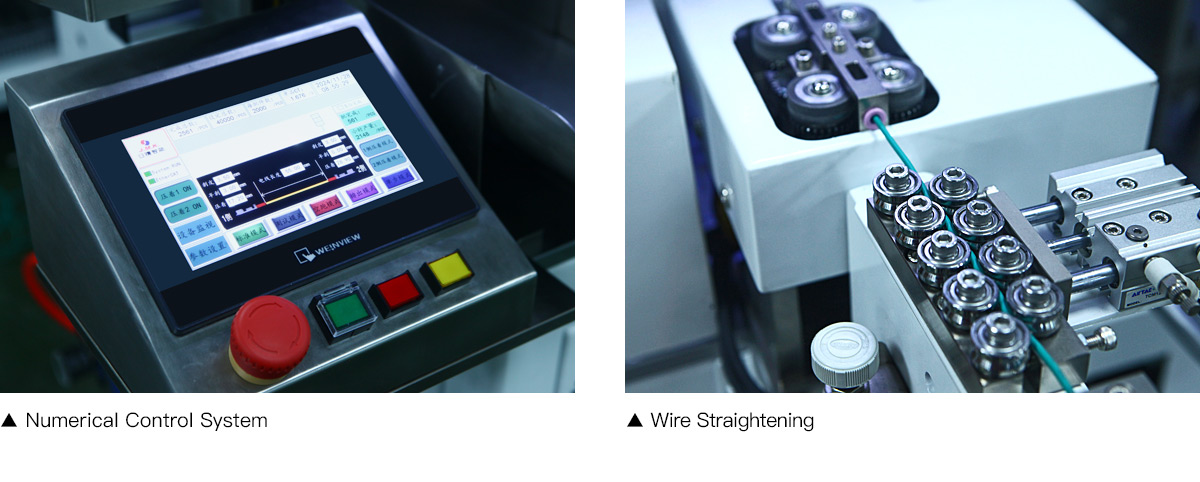

4.Runs on an industrial-grade computer operating system, offering a user-friendly and intuitive interface.

5.Supports both manual and automatic debugging modes, making equipment setup faster and more efficient.

6.Equipped with a servo-driven crimping system that maintains a stable compression ratio, fully meeting cross-sectional analysis standards.

Technical Parameters:

|

Model |

JM-03+ Fully automatic double-head terminal crimping machine |

|

Function |

Wire cutting, Single and dual-end stripping, Dual-end crimped, Defective product sorting. |

|

Capacity |

About)4500pcs/H (Minimum wire cutting time) |

| Wire range |

AWG#16-#30 (Customizable) |

| Cutting length |

30mm-9999mm |

| Stripping length |

0-20mm |

|

Crimp Abiliy |

2T Crimping Machine*2 sets |

|

Control System |

PLC |

| Voltage | AC22V/50HZ 10A |

| Air supply | 0.5MPa,About 170N/min |

|

Environment |

Temperature:5°C-50°C inside;Humidity:30%-80%RH |

|

Size |

W1140 * D670 *H1400mm(No protrusions) |

|

Weight |

About450kg |

Product Details: