Sales Tel

+86-18928379199

|  |  |

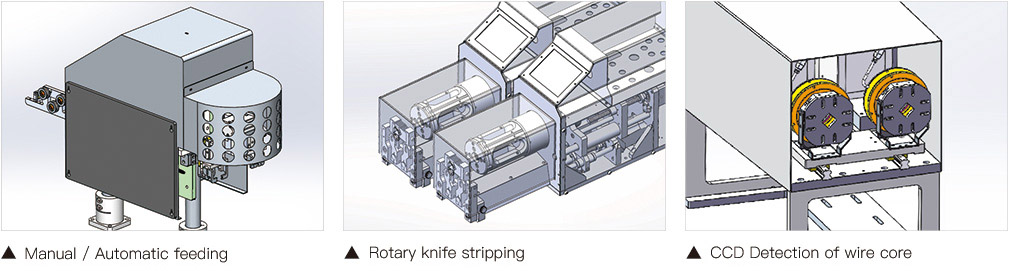

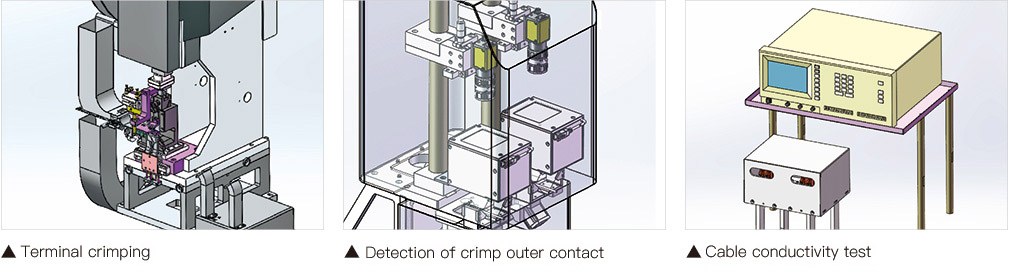

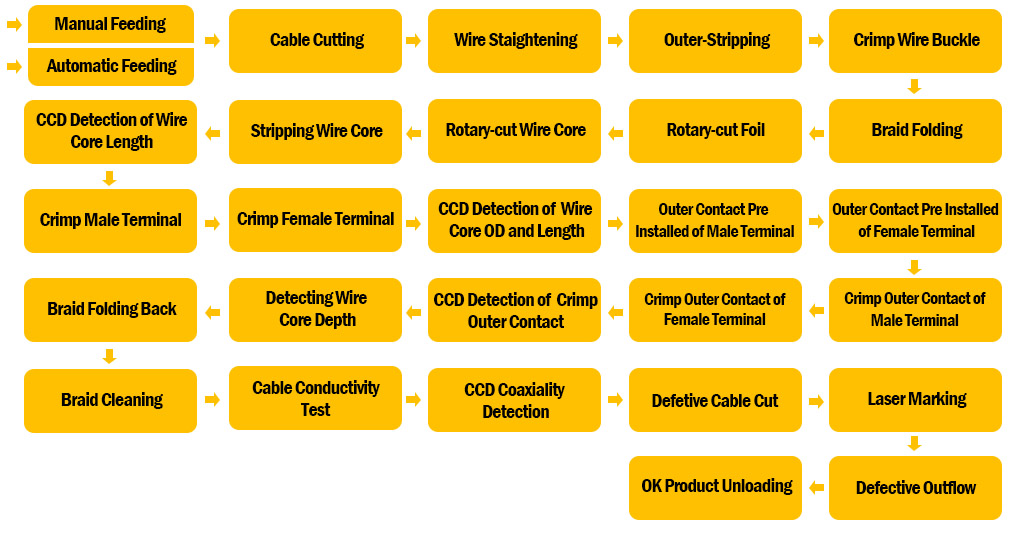

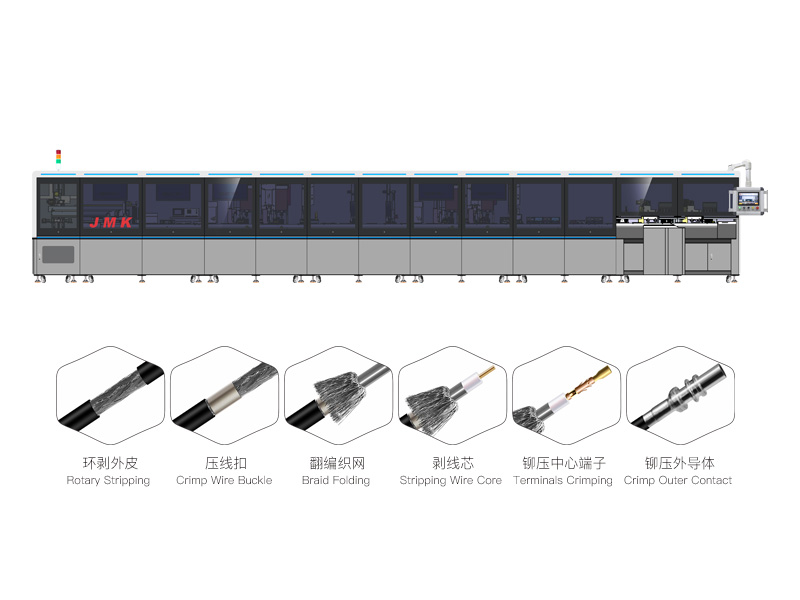

Rotary Stripping/Crimp Wire Buckle/Braid Folding/Stripping Wire Core /Terminals Crimping/Crimp Outer Contact

Product Features:

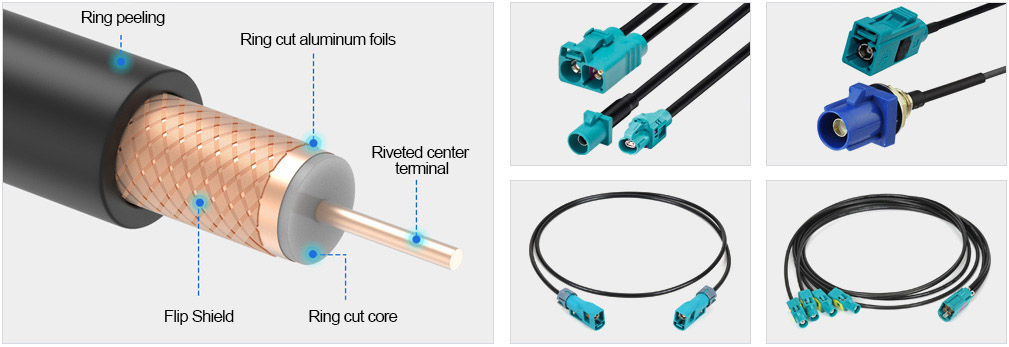

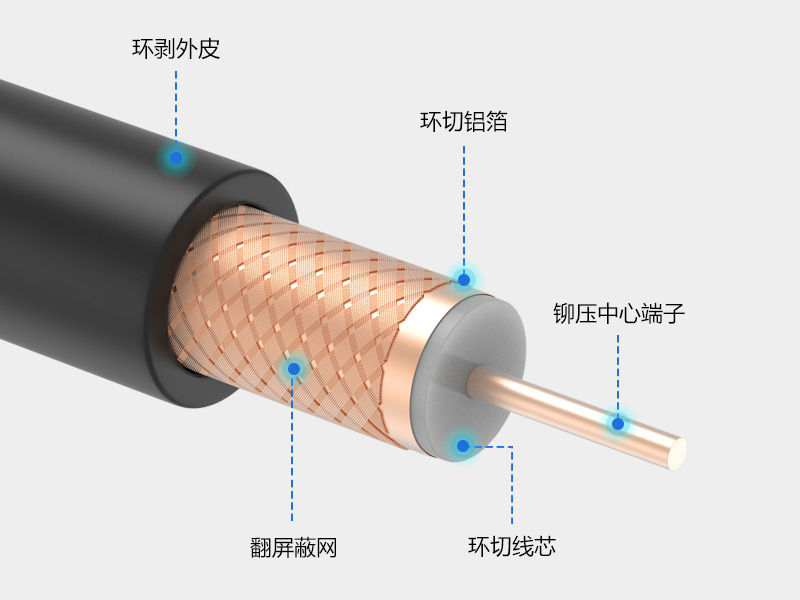

JM-900 Fakra machine line is mainly used for processing the RF cable, high level of automation and product quality control, which save the labor cost. it can realize processing and inspection ofwire jacket, shield net, foil, inner and outer conductor.

Product Description:

1.Full servo driving system, the main bus cable use the Mitsubishi controller and fiber cable communication which has stable performance

2. Mitsubishi GT2000 touch screen operation, optional with mobile tablet communication, convenient single station debugging

3. It Mainly uses Keyence displacement sensor and Cognex camera detection to ensure processing accuracy

4. The machine is installed with OES to monitor the crimping force during the production

5. Formula database system, storage one-key switching, operation authority management, product data tracking.

6. This equipment can be widely used in automatic processing of Fakra wire harness in the fields of vehicle communication, remote diagnosis, audio equipment, broadcast antenna and so on.

Technical Parameter:

| Model | JM-900 FAKRA/Ethernet automated production line |

|

Capacity |

Approx. 6s/pcs (at shortest cut) |

| Wire range |

2.5-3.5mm2 coaxial cable |

| Cutting length |

100mm-5000mm |

|

Stripping length |

0-20mm |

| Cutting precision |

±0.5%xL |

|

Crimp force |

4T servo crimping machine x4 units |

|

Detecting device |

Low pressure, wire deteclion, wire overload detection, pressing error, presence of terminals and overload deteclion. cable conductivity test, pressure monitoring and CCD visual inspection. |

|

Control |

PLC |

|

Power supply |

AC380V 50/60Hz three-phase |

|

Temperature |

5°C - inner 50°C |

|

Humidity |

30%-80%RH (no condensation) |

|

Size |

L12500 × W2260 × H1965mm |

| Weight | 10T |

Product Details: