Sales Tel

+86-18928379199

|

Product Introduction:

The gas consumption is halved without a wire feeder; this machine is designed to reduce volume, pursue function and high performance-to-price ratio; servo motor is used for automatic positioning at both ends; double drive is adopted for wire feeding, which provides mechanical productivity and reliability; peeling at both ends and pressing at both ends; 5200pcs/H for the shortest tangent.

Product Feature:

1. Features a fully closed-loop flexible wire feeding system with a rubber belt mechanism to protect the wire surface and enhance feeding accuracy.

2. Incorporates a network-driven system to meet the rigorous industrial processing demands of photovoltaic wires.

3. Utilizes imported servo motor drives to ensure high precision, efficiency, and operational stability.

4. Runs on an industrial-grade computer operating system, offering a user-friendly and intuitive interface.

5. Supports both manual and automatic debugging modes, making equipment setup faster and more efficient.

6. Equipped with a servo-driven crimping system that maintains a stable compression ratio, fully meeting cross-sectional analysis standards.

Technical Parameters:

| Model | JM-07 |

| Speed | 5200pcs/H(Shortest Tangent |

| Applicable wire | AWG1007 16#~30# |

| Cutting length | The shortest length of 20mm~9999mm depends on the stripping length |

|

Cutting precision |

±0.1mm(design 0.005x total length) |

|

Stripping length |

1 side 10mm 2 side 10mm |

| Crimping force |

19600N(2T) |

|

Control method |

Single chip microcomputer control |

| Inspect equipment |

Detect abnormalities such as low pressure and shutdown |

| Voltage |

220V |

| Air supply |

0.5Mpa(5kgf/cm)~200NL/Min |

|

Size And Weight |

1140Wx670Dx1400H(mm)450kg |

Tips:The machine capacity is only theoretical data, the actual capacity is related to the size of the wire and the size of the terminal, depending on the actual capacity. (The right of interpretation belongs to Nissei Electro-Mechanics)

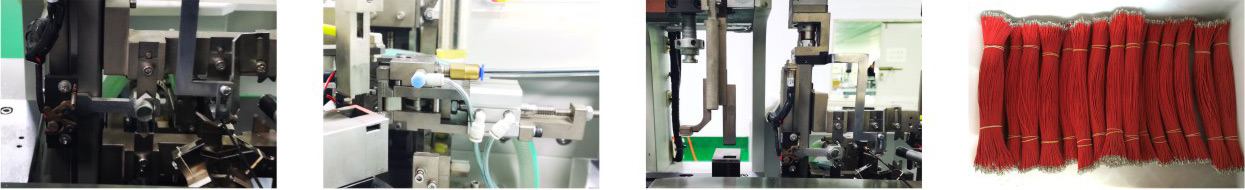

Product Details: