Sales Tel

+86-18928379199

|

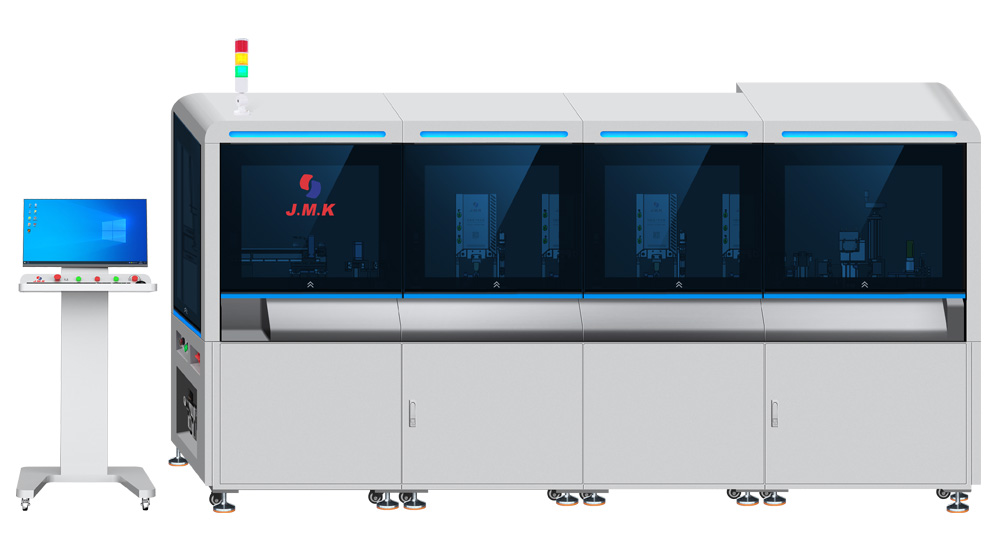

Product Introduction:

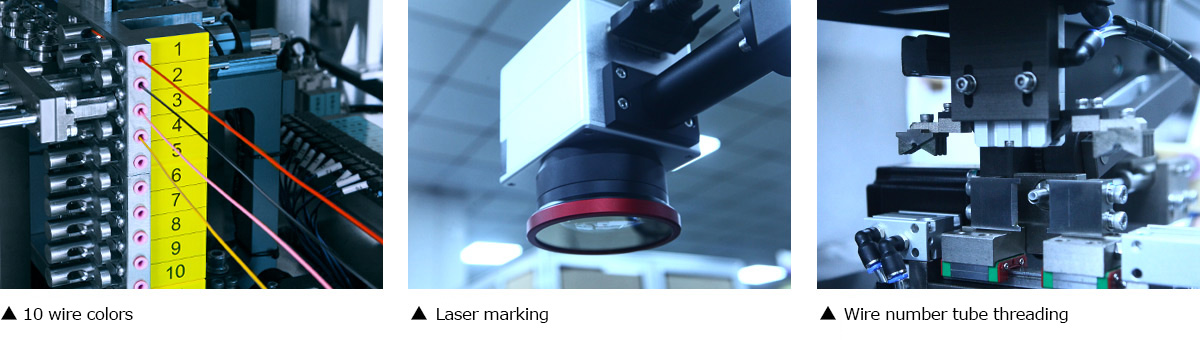

Supports U-shaped wires and up to 10 wire colors.

Features multi-position terminal crimping, double-piercing numbered tubes, and heat shrinking.

Compatible with various terminals and wire types, enabling fast and flexible changeovers.

Equipped with industrial-grade laser marking for clear, consumable-free printing and high stability.

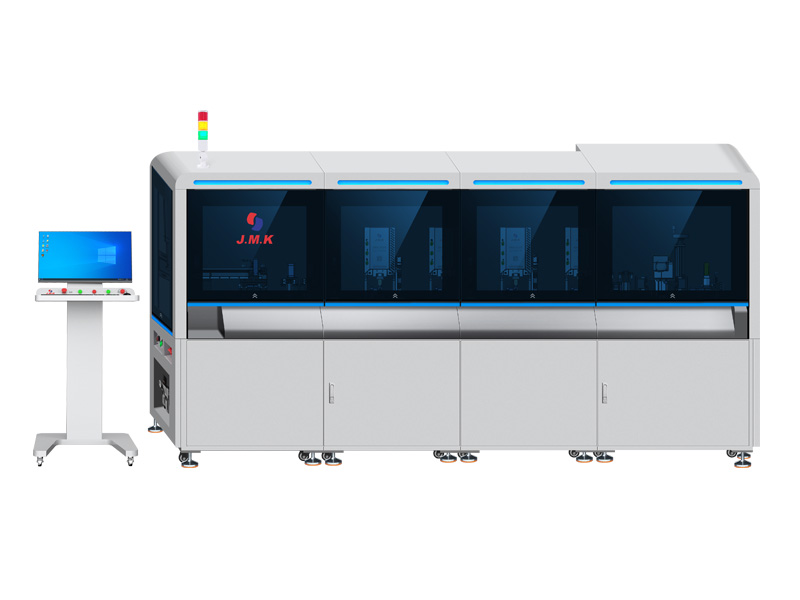

Streamlined multi-station design delivers smooth operation and high efficiency—up to 1800–2300 pieces/hour.

Optional pressure monitoring and visual inspection ensure real-time crimp quality and full-process control.

Product Feature:

1.Features a fully closed-loop flexible wire feeding system with a rubber belt mechanism to protect the wire surface and enhance feeding accuracy.

2.Incorporates a network-driven system to meet the rigorous industrial processing demands of photovoltaic wires.

3.Utilizes imported servo motor drives to ensure high precision, efficiency, and operational stability.

4.Runs on an industrial-grade computer operating system, offering a user-friendly and intuitive interface.

5.Supports both manual and automatic debugging modes, making equipment setup faster and more efficient.

6.Equipped with a servo-driven crimping system that maintains a stable compression ratio, fully meeting cross-sectional analysis standards.

Technical Parameters:

|

Model |

JM-201U JM-201U Automatic Wire Crimping Machine (Dual-end Number Tube Insertion & Multi Station Terminal Crimping Machine) |

|

Function |

Wire cutting,single/dual-end stripping,multi station terminal crimping,laser printing,tube inserting and heat shrink. |

|

Wire color |

Ten colors |

|

Cutting length |

260mm~9999mm |

|

Stripping length |

0~15mm |

|

Insertion spec |

JM-201U Fully Automatic Multi-station Tube Threading Machine Sleeve Length 12~30mm,Center 2.0~4.0mm |

| Printing type | Laser |

|

Crimping force |

2T Servo Crimping Machine x4(Customized) |

|

Detecting device |

Air pressure detection, no wire/no terminal detection; Wire cutting length detection. Optional: CCD, Compression force monitoring. |

|

Control |

PLC |

|

Compressed air |

0.5~0.7Mpa(about 130N/min~170N/min) |

|

Power supply |

AC220V/50/60Hz 16A |

| Size |

L3600xW850xH1900mm |

| Weight | About 2000kg |

Product Details:

Wiring Harness Case:

The JM-201U Automatic Wire Crimping Machine (Dual-end Number Tube Insertion & Multi Station Terminal Crimping Machine) can be widely applied in the electrical wiring industry, such as harness processing for high and low voltage cabinets, complete distribution cabinets, switchgear cabinets, and control cabinets. The equipment is primarily designed for automated secondary harness processing, adapting to diverse production needs.