Sales Tel

+86-18928379199

|

Product Feature:

1.Features a fully closed-loop flexible wire feeding system with a rubber belt mechanism to protect the wire surface and enhance feeding accuracy.

2.Incorporates a network-driven system to meet the rigorous industrial processing demands of photovoltaic wires.

3.Utilizes imported servo motor drives to ensure high precision, efficiency, and operational stability.

4.Runs on an industrial-grade computer operating system, offering a user-friendly and intuitive interface.

5.Supports both manual and automatic debugging modes, making equipment setup faster and more efficient.

6.Equipped with a servo-driven crimping system that maintains a stable compression ratio, fully meeting cross-sectional analysis standards.

|

Model |

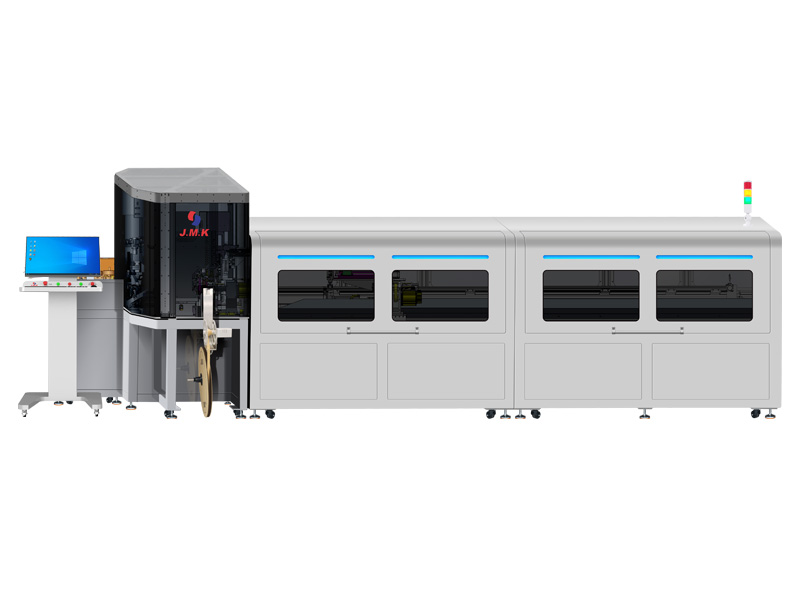

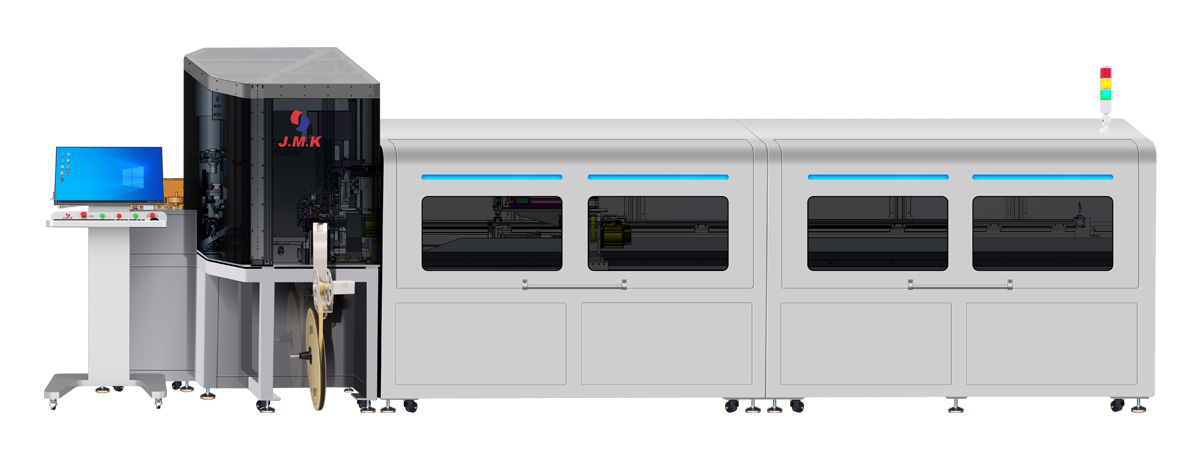

JM-560 Automatic Crimping Machine (Cutting/Stripping Wire Twisting Waterproof Seals Inserting) |

|

Function |

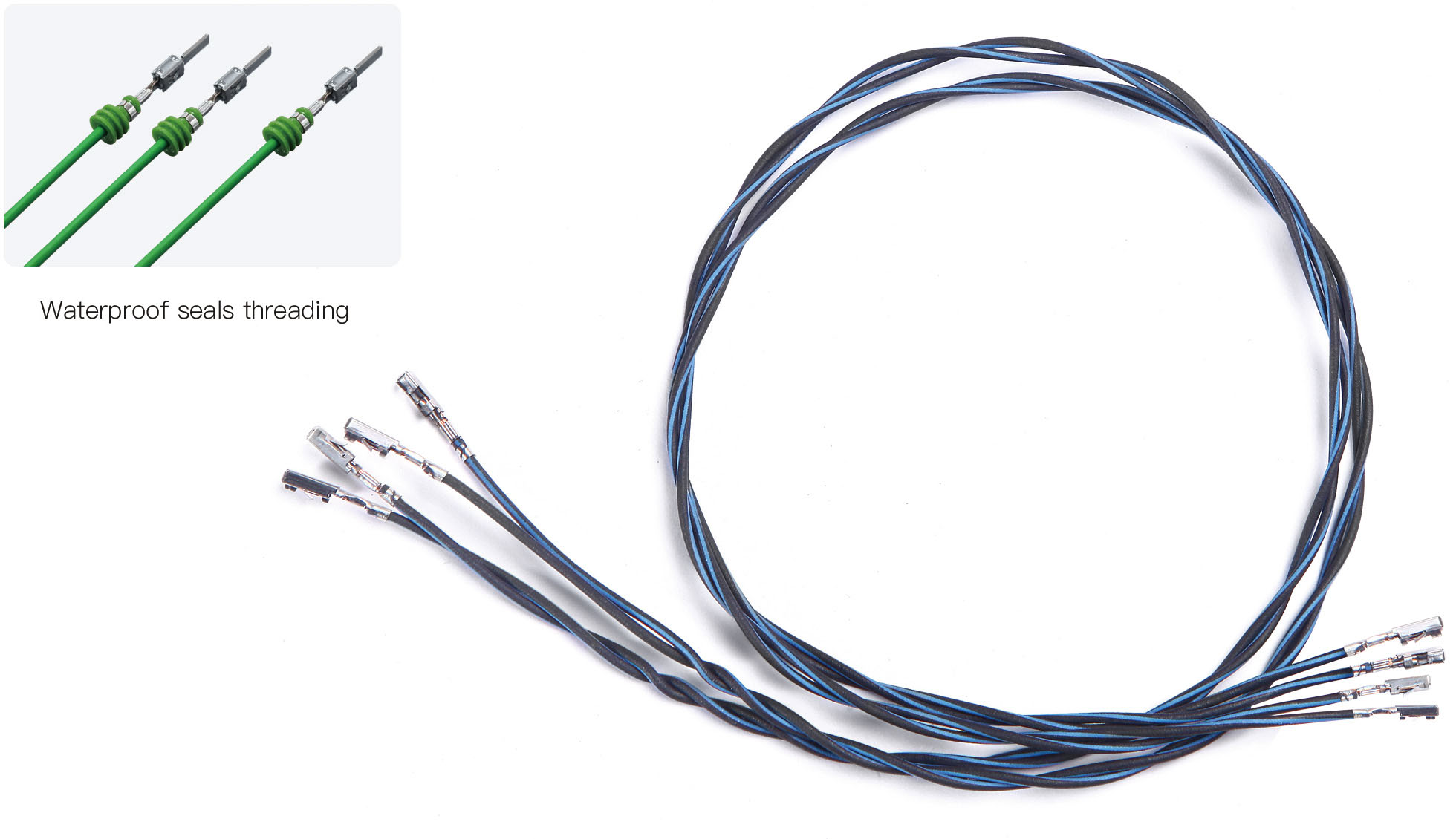

Wire cutting and stripping, Single / dual-end crimping, waterproof seals inserting, wire twistina. connected to MES |

|

Wire color |

Two colors |

|

Cutting length |

300mm~4000mm |

| Cutting precision |

±0.3%xL |

| Stripping length |

0~18mm |

|

Crimping force |

4T servo crimping machine x2 sets |

| Twist pitch | (5-80)±10% |

| Mould | OTP |

|

Detecting device |

Air pressure detection, no wire / no temminal detection: Optional: Compression force monitoring, CCD,Waterproof Seals Station. |

|

Control |

PLC |

|

Compressed air |

0.5~0.7Mpa(about 130N/min~170N/min) |

|

Power supply |

3-phase AC380V/50/60Hz 60Hz |

| Size |

L6300xW1800xH2000mm |

| Weight |

About 2000kg |