Sales Tel

+86-18928379199

|  |  |  |

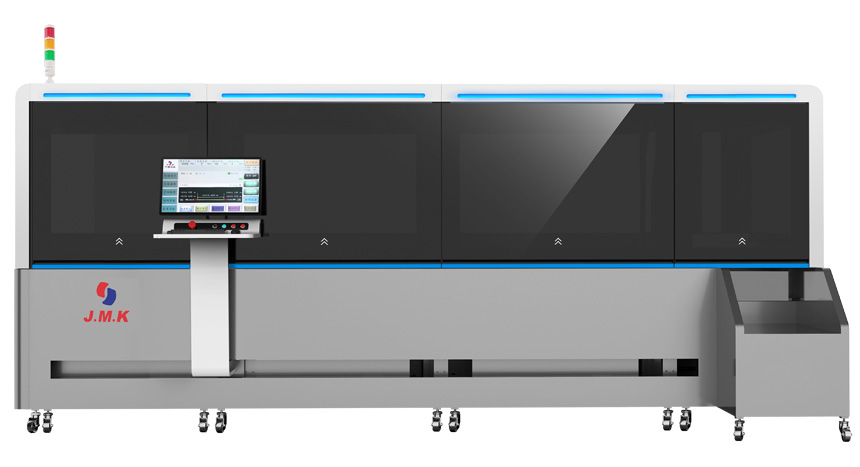

Product Introduction:

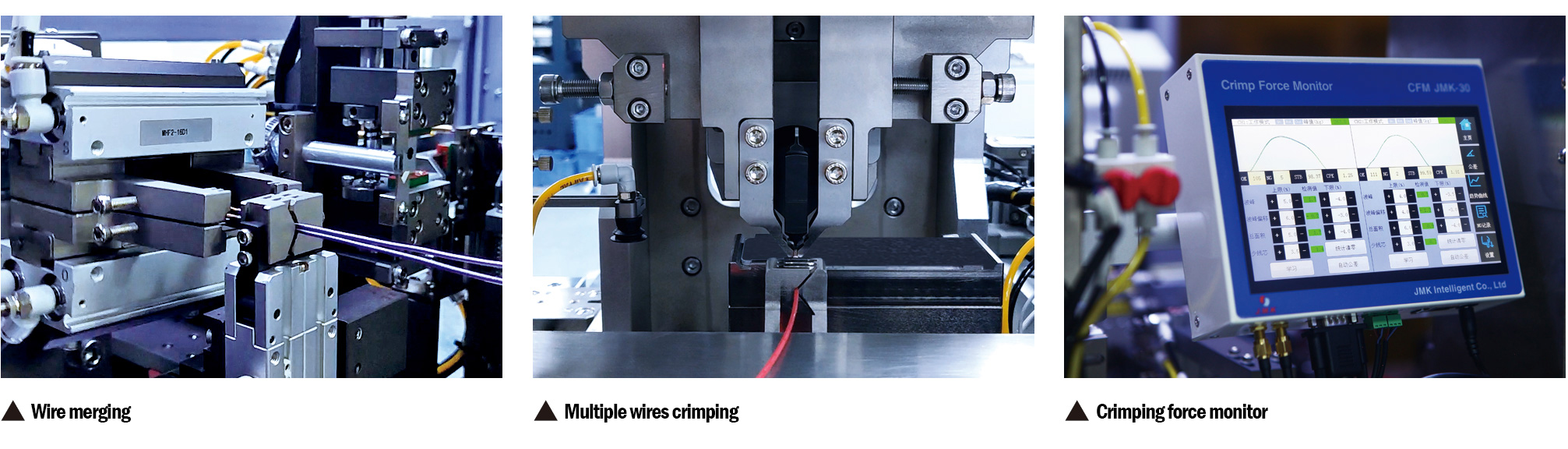

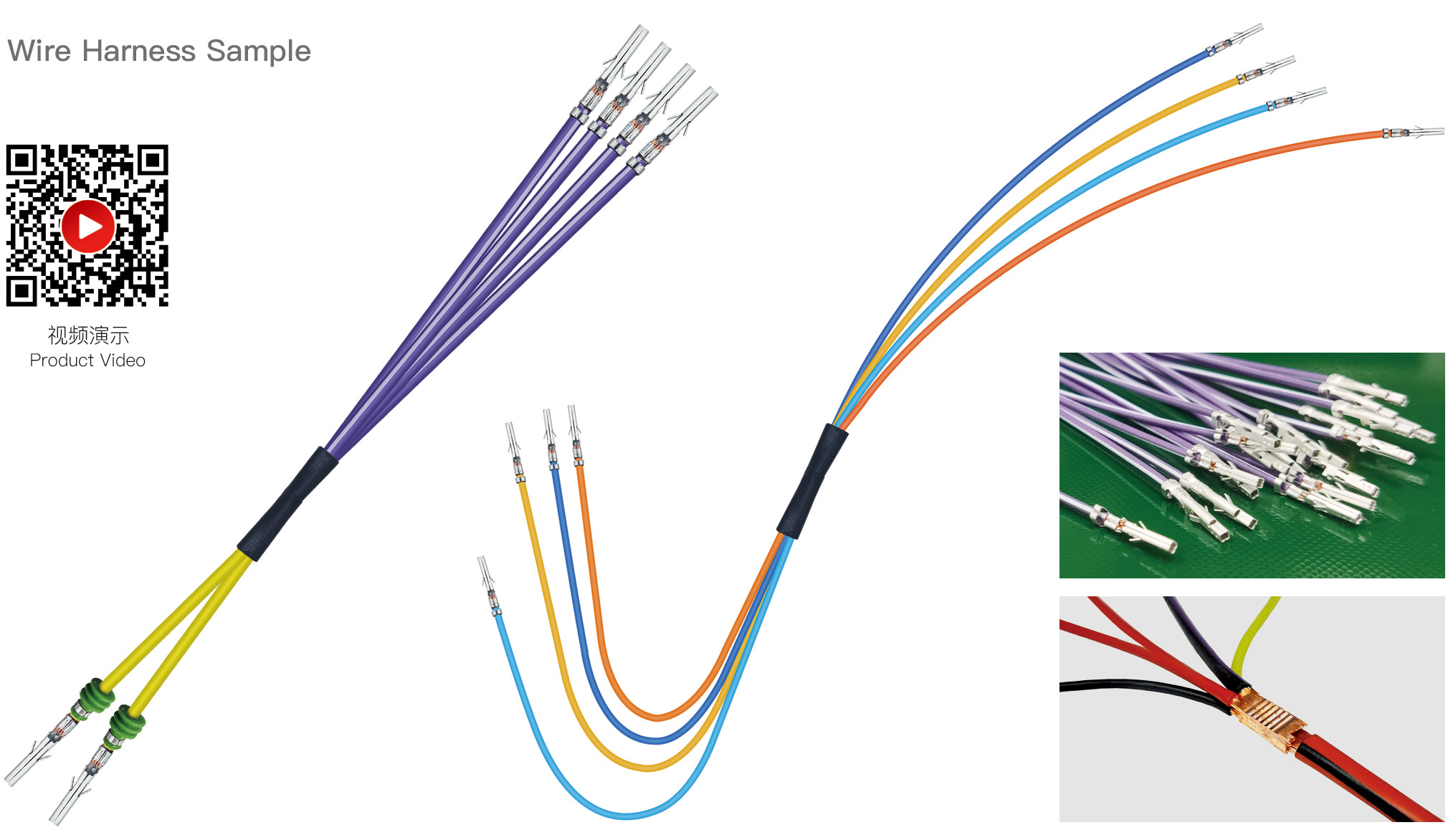

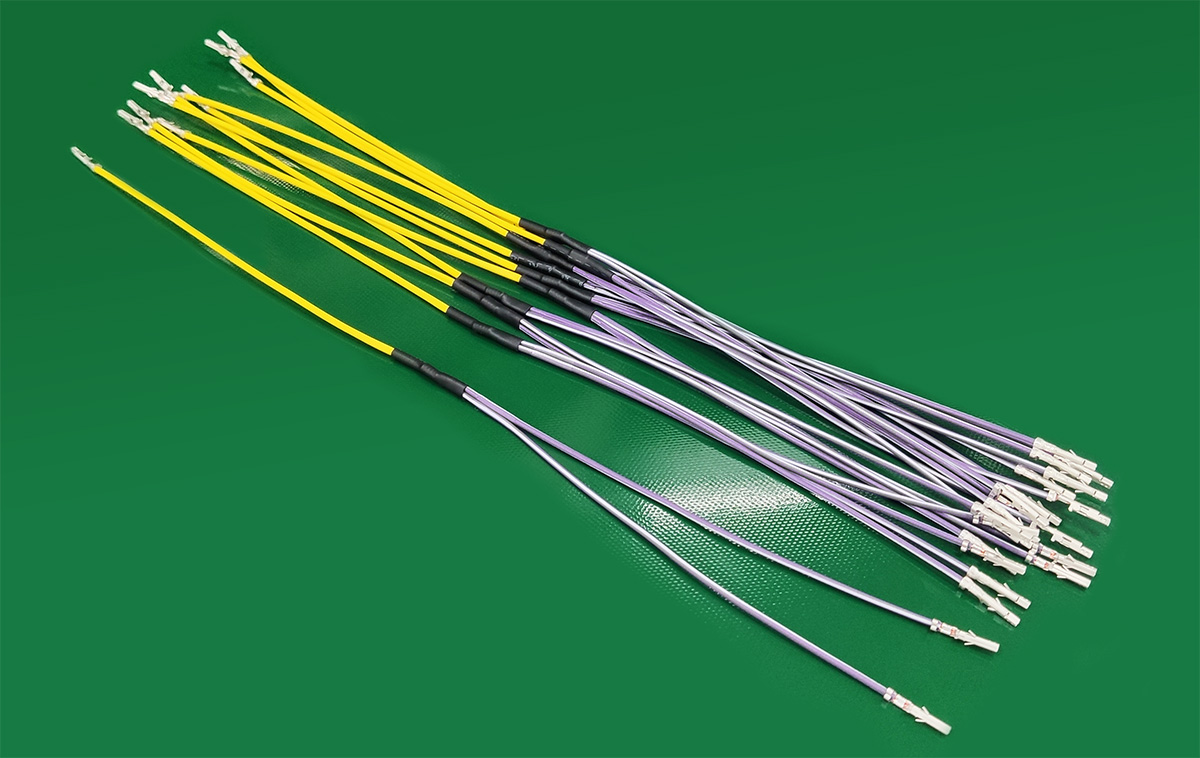

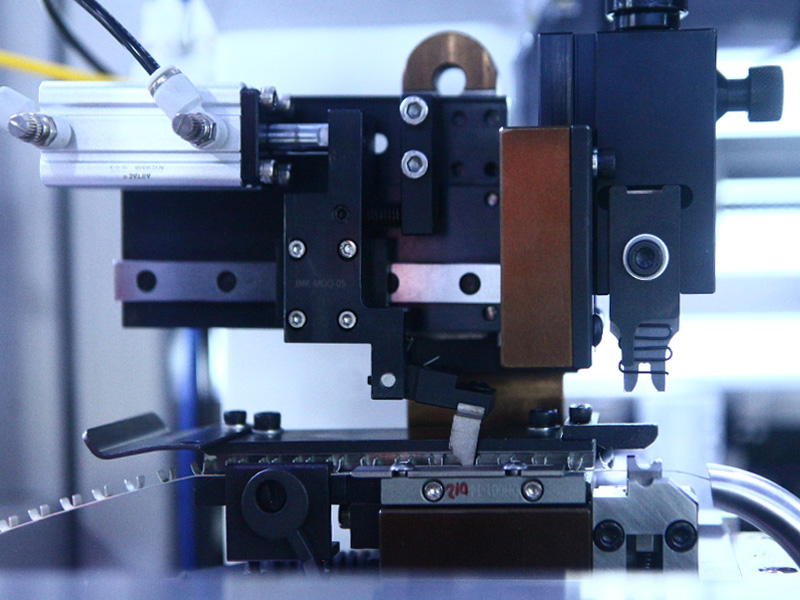

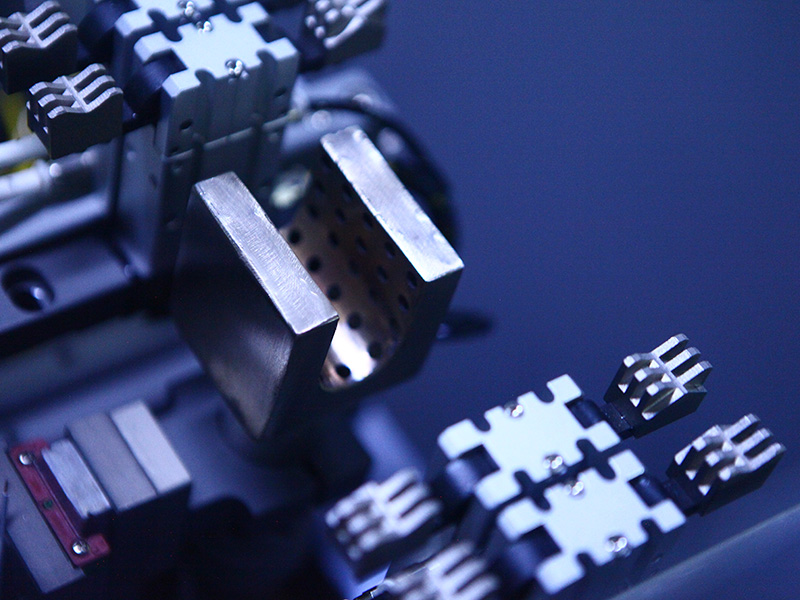

JM-300B Multiple wires combined together ultrasonic welding machine, It can crimp a single wire to multiple wires, or multiple wires to multiple wires, compatible with both long and short wires. Support multiple wire color, cutting and stripping, multi station crimping, merging, ultrasonic welding or terminal crimping, heat shrinkable tube threading, waterproof plugs threading and other processes. Optional crimping force monitor and CCD visual inspection system, It can effectively detect defects in terminal crimping, and sort out defective products.

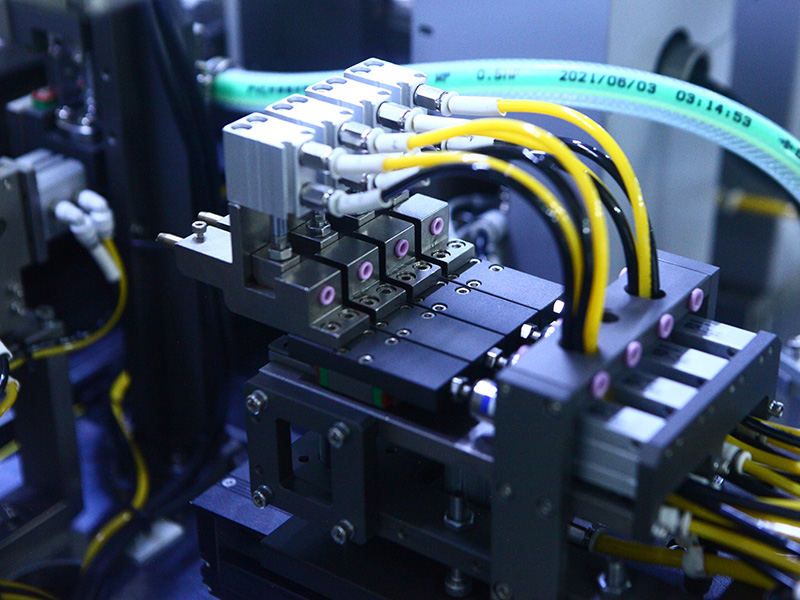

1.Features a fully closed-loop flexible wire feeding system with a rubber belt mechanism to protect the wire surface and enhance feeding accuracy.

2.Incorporates a network-driven system to meet the rigorous industrial processing demands of photovoltaic wires.

3.Utilizes imported servo motor drives to ensure high precision, efficiency, and operational stability.

4.Runs on an industrial-grade computer operating system, offering a user-friendly and intuitive interface.

5.Supports both manual and automatic debugging modes, making equipment setup faster and more efficient.

6.Equipped with a servo-driven crimping system that maintains a stable compression ratio, fully meeting cross-sectional analysis standards.

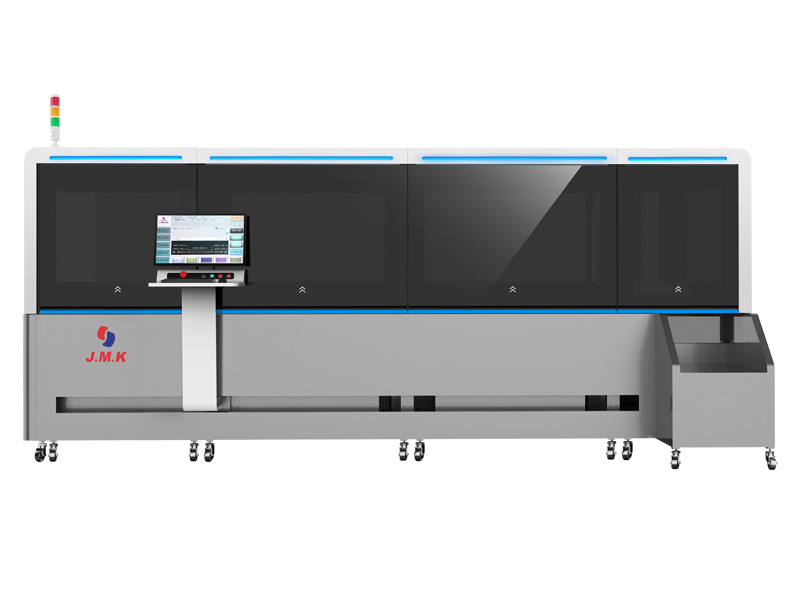

| Model name | JM-300B Multiple Wires Combined Together Ultrasonic Welding Machine |

| Function | Wire cutting, single/double end stripping, crimping, wire jointing, heat shrink tubing, heat shrinking, supporting one-to-many and many-to-many jointing |

| Wire Specifications | 0.3-6mm², AWG26#-AWG10#((Support customization) |

| Wire Color | 4 wire color (Support customization) |

| Cutting length | 100mm-4000mm |

| Stripping length | 1-10mm |

| Pipe specifications | Φ2.0-8.0mm |

| Crimp strength | 2.0T×5 5 units |

| Applicable mold | Universal OTP mold |

| Detection device | Air pressure detection, wire detection, crimp terminal detection, pressure monitoring (optional) |

| Control method | PLC |

| Efficiency | CT: 4s/pcs, about 900-1200pcs/hour (depending on the specific wire material) |

| Compressed air | 5MPa~7MPa (air volume used is about 130N/min~170N/min) |

| Power supply | AC380V/50Hz 10KW |

| Dimensions | Length 4500 × Width 2500 × Height 1800mm |

| Weight | About 2200kg |